THD800 XL FOOD

8 STATIONS SERVO DRIVEN FILLING SEALING MACHINE FOR DOYPACK® STAND UP POUCH

-

BEVERAGE IN DOYPACK® STAND UP POUCH

-

COOK DISH IN DOYPACK® STAND UP POUCH

-

MAPLE SYRUP IN DOYPACK® STAND UP POUCH

-

prepartion for cake in DOYPACK® stand up pouch

DOYPACK® PREMADE POUCH

EASY MAINTENANCE

EASY CLEANING AND ACCESSIBILITY

SERVO DRIVEN

FLEXIBILITY (MONO/DUO/TRIO MODE)

MINIMAL FOOTPRINT

OUTPUT: UP TO 135 POUCHES/ MIN

POUCHES VOLUME: FROM 50 ML TO 5 L

FOOD

CHEMICAL/DETERGENT INDUSTRIES

CONCENTRATED DÉTERGENTS, POWDERS OR LIQUIDS, COOLANTS,

DISTILLED WATER, PAINT, MOTOR OIL, WINDSCREEN WASHER

FLUID…

COSMETIC /PHARMACEUTICAL INDUSTRIES

LIQUID SOAP, CREAMS, SHAMPOO, STERILE WATER, BODY OIL…

-

INVERTED STAND UP POUCH

INVERTED STAND UP POUCH -

SHAPED POUCH

SHAPED POUCH -

SHAPED STAND UP POUCH WITH TOP CAP

SHAPED STAND UP POUCH WITH TOP CAP -

SPOUTED POUCH WITH CAP ON THE CORNER

SPOUTED POUCH WITH CAP ON THE CORNER -

SPOUTED POUCH WITH TOP CAP

SPOUTED POUCH WITH TOP CAP -

STRAIGHT POUCH

STRAIGHT POUCH

TECHNICAL SPECIFICATIONS

DESIGNED FOR WORKING IN DIFFICULT AND AGGRESSIVE ENVIRONMENTS, THE THD800 XL IS PERFECTLY ADAPTED TO FILL AND SEAL THE PREMADE DOYPACK® STAND UP POUCHES (WITH OR WITHOUT CAPS / HANDLES).

8 STATIONS (up to 3 dosing stations) allow various lay outs for filing, sealing and fiting accessories. Secured by the carrousel grippers, the pouches are opened, filed, sealed, cooled and ejected.

Motions (rotation of the turret, opening grippers and regulations) are controlled by servo-motors.

The THD800 XL has been built to facilitate adjustments. It is able to package in “MONO” (1 pouch/cycle), “DUO” (2 pouches/cycle) or “TRIO” mode (3 pouches/cycle).

An integrated programmable logic controller (in several languages) and one state of the art electronics ensure high precision performances and repeatability throughout simple operating commands.

A storage capacity of 100 programs favors a fast change of sizes.

STANDARD EQUIPMENT

Welded steel structure mechanic, covered with stainless steel protections

Easy cleaning of production enclosure:

No contact between delicate parts and the dosed product

Access through transparent doors to the workstations with integrated security system

Motions of the carrousel and grippers are controlled by servo-motors

Defects historisation and programmable logic controller

Recording and storage of an infiite number of recipes

Continuous adjustment of mechanical speed from 10 to 60 cycles/min depending on pouch volume and product type (displayed on touch screen)

ACCESSORIES

Ink jet date coding / laser

Injection of neutral gas or steam

Dosing device for liquid/viscous products (pumps, electromagnetic or mass flw meters...) or solid products (grains, powders using auger filers, or MHW or bucket elevator)

Ultrasound sealing

Exit conveyor

Ultra-clean version (laminar flw, steam sterilisation...)

Automatic spouted pouches loarder

Filling juices

UNITED ARAB EMIRATES

Full SD4 line [Doypack® pouch] and D6-5 [hot filling of 200 ml sta nd-up pouches]

- High output filling [15 000 pph]

- Flexibility of the line operation

Filling condensed sweetened milk, cream

COLOMBIA

Ultra-clean TD1000 DUO machine

- Specific design for Nestlé

- Clean dosing

- Efficiency of the sealing

- Respect of the hygienic requirements

Filling honey in SUP DOYPACK®

FRANCE

THD800 machine with lobes pump and electromagnetic flowmeter

- High accuracy for a product with a variable viscosity

Filling edible palm oil in SUP DOYPACK®

INDONESIA

TD1500 machine

- Clean dosing

- Efficiency of the sealing

- Production flexibility

More information

DJAZAGRO - ALGER - 7th to 10th April

Come and visit us at DJAZAGRO the trade show for agro food production.

We will HALL C booth A070

CFIA 2025 - FROM 4 TO 6 MARCH, 2025

Thimonnier will exhibit in CFIA, at the french benchmark event for the food-processing sector.

Come to visit our booth HALL10 C28 !

HAPPY NEW YEAR !

2025 !

A new year for new projects

ALL4PACK - FROM 4TH TO 7TH NOVEMBER 2024

Thimonnier will exhibit in ALL4PACK fair in order to present its filling solutions in flexible packaging for food, cosmetics, detergents, industry and healthcare.

ASOLECHE - Colombia - 5th to 6th June

Come and see us in Colombia at the 11th International Dairy Industry Congress in Medellin.

DJAZAGRO - ALGER - 22th to 25th April

Come and visit us at DJAZAGRO the trade show for agro food production.

We will HALL C booth A048

Anuga Food Tec, Koln 19-22 March 2024

Come visite us at ANUGA FOOD TEC exhibition in Köln from March 19th 22th, 2024

Our sales team will welcome you to our stand hall 8.1 stand F-089.

ANDINA PACK - BOGOTA COLOMBIA

Starting November 27 th, 2023, to the 30th, Thimonnier and SUPPLIES COLOMBIA will exhibit side by side at the ANDINA PACK fair.

PROD & PACK - LYON EUREXPO

Come and visit us at PROD&PACK the only event dedicated to the packaged product ecosystem.

DJAZAGRO - ALGER - 5th to 8th June.

Come and visit us at DJAZAGRO the trade show for agro food production.

We will HALL C booth B044

CFIA 2023 - FROM 14 TO 16 MARCH, 2023

Thimonnier will exhibit in CFIA, at the french benchmark event for the food-processing sector.

Come to visit our booth HALL10 C2 ! 🙂

HAPPY NEW YEAR !

Thimonnier wishes you all the best for 2023 !

ALL4PACK - FROM 21TH TO 24TH NOVEMBER 2022

Thimonnier will exhibit in ALL4PACK fair in order to present its filling solutions in flexible packaging for food, cosmetics and detergents.

GULFOOD MANUFACTURING - From 8th to 10th november 2022

Come to visit our booth HALL 1 S1-B10 during GULFOOD MANUFACTURING

PACK EXPO CHICAGO - from October 21 to 26, 2022

Starting October 23rd, 2022, to the 26th, Thimonnier and HOOD PACKAGING will exhibit side by side stand N5568 at the Chicago PACK EXPO

Anuga Foodtech, Koln 26-29 April 2022

Come visite us at ANUGA FOODTEC exhibition in Köln from April 26th 29th, 2022

Our sales team will welcome you to our stand hall 8 stand E-048 and will be pleased to present its innovations

CFIA Rennes 2021 fair - June 9-10-11, 2021

Agri-food innovation is always being invented here!

You were eager to make your projects a reality? Now is the time.

Come and meet the THIMONNIER SAS team Hall 10 Stand C2.

Thimonnier strengthens its expertise eco-friendly flexible packaging with Frutonic, Switzerland

Frutonic has selected Thimonnier solution with its SF102 spout filling machine for DOYPACK® pouches with cap to pack bio-products in an eco-friendly way in 100% recyclable PP mono-material packaging (pouch and cap).

Thimonnier welcomes students from Claude BERNARD University in QIAC Licence 3

Sylvie GUINARD, President of Thimonnier, was pleased to welcome last Friday, May 11, 14 students from this third school year as part of their teaching module "Packaging & Packing" .

NEW AVAILABLE VIDEO OF SPOUT FILLING MACHINE SF102

Discover the new video of the spout filling line for DOYPACK® stand up pouches with cap

The inverted pouch, a trendy and promising new format ...

Thimonnier, once again pioneer in packaging solutions for flexible pouch with the inverted pouch. Discover the amazing characteristics of this innovative packaging that directly competes with traditional rigid plastic and glass containers....

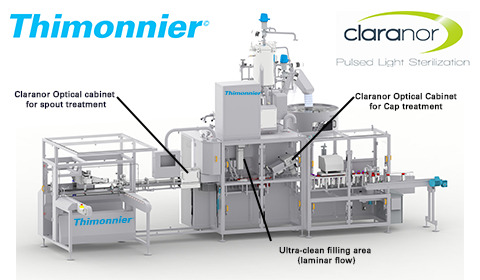

THIMONNIER & CLARANOR partners for an ULTRA CLEAN packaging line for dairy products in DOYPACK® & inverted stand up pouches !

Thimonnier Strengthens its expertise regarding dairy products in flexible pouches with its SF102 Ultra Clean spout filling line thanks tor Pulsed Light decontamination from Claranor.

NEW AVAILABLE DEMONSTRATION OF FILLING MACHINE FOR DOYPACK®

Discover the new version of the filling machine for DOYPACK®,THD900, in DUO mode (2 pouches/cycle)

DJAZAGRO - ALGER - 7th to 10th April

Come and visit us at DJAZAGRO the trade show for agro food production.

We will HALL C booth A070

CFIA 2025 - FROM 4 TO 6 MARCH, 2025

Thimonnier will exhibit in CFIA, at the french benchmark event for the food-processing sector.

Come to visit our booth HALL10 C28 !

HAPPY NEW YEAR !

2025 !

A new year for new projects

ALL4PACK - FROM 4TH TO 7TH NOVEMBER 2024

Thimonnier will exhibit in ALL4PACK fair in order to present its filling solutions in flexible packaging for food, cosmetics, detergents, industry and healthcare.